China Invents ‘Bone Glue’ That Can Fix Broken Bones in Just Minutes With One Injection

Surgeons spent hours reconstructing shattered bones, piece by tiny piece, knowing their patients faced months of recovery and another surgery to remove hardware. One young resident physician watched these lengthy operations in 2016 and wondered whether medicine was missing something obvious. Years later, while crossing a bridge, he noticed something clinging to underwater pilings that would change orthopedic surgery forever.

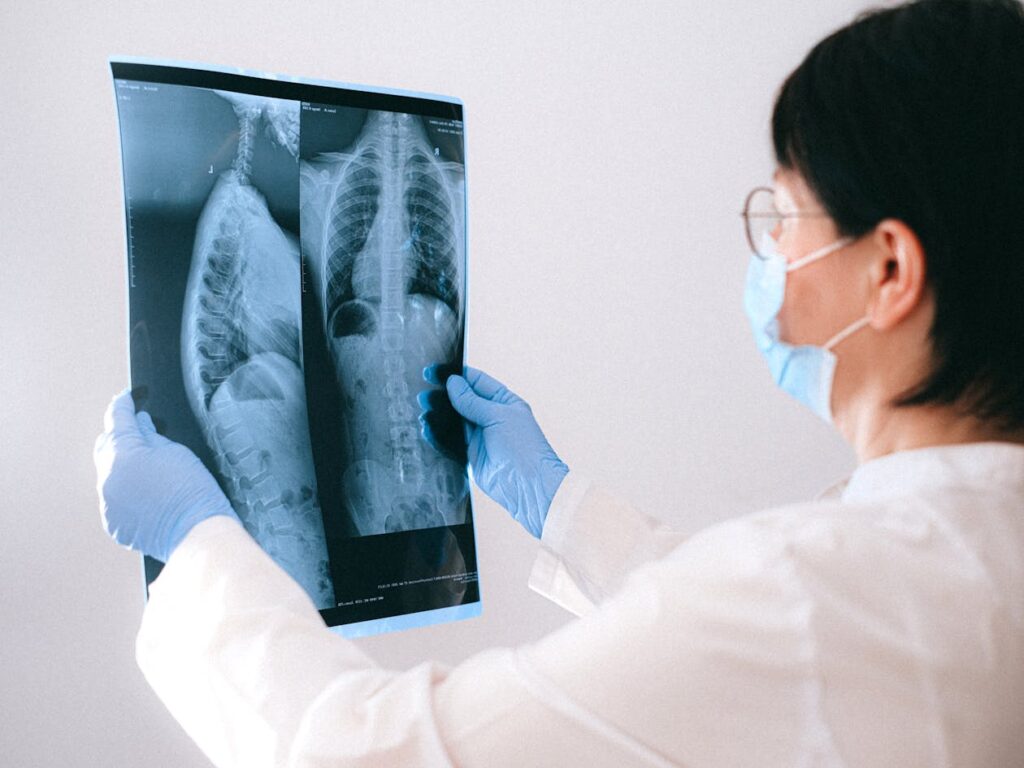

Nature solved a problem that stumped medical science for decades. Creatures attach themselves to wet, moving surfaces where conventional adhesives fail miserably. Scientists in China studied this natural phenomenon and created something that bonds broken bone fragments in three minutes flat using nothing but a single injection through a tiny incision.

Over 150 patients have already experienced healing that replaces metal plates, eliminates second surgeries, and cuts recovery complications dramatically. What seemed impossible just became reality through technology inspired by something you might eat at a seafood restaurant.

Three Minutes to Fix What Used to Take Months

Chinese researchers at Zhejiang University developed medical adhesive called Bone-02 that represents a paradigm shift in fracture treatment. Single injection delivers bonding material directly to fracture sites where it sets almost immediately, holding shattered fragments in precise alignment.

Revolutionary alternative to metal plates and screws emerged from years of experimentation overcoming technical challenges that defeated previous attempts at bone adhesives. Research team led by Lin Xianfeng, associate chief orthopedic surgeon at Sir Run Run Shaw Hospital, announced successful clinical trials demonstrating both safety and effectiveness.

Traditional fracture repair requires large incisions, extensive hardware installation, and subsequent removal surgery. Bone-02 eliminates these steps entirely while achieving superior outcomes in fraction of time. Patients walk away with smaller scars, less pain, and no foreign objects permanently embedded in their bodies.

Clinical trial results showed excellent performance across diverse fracture types and patient populations. Multi-center randomized controlled studies confirmed that this approach works consistently under real-world surgical conditions rather than just laboratory settings.

Oysters Hold Secret to Healing Human Bones

Lin observed shellfish firmly attached to bridge pilings underwater during routine activities away from hospital. Oysters cling to surfaces in harsh ocean environments where salt water, constant motion, and pressure would destroy ordinary adhesives within moments.

Bio-cement mechanism oysters secrete works through protein-rich substance that forms chemical bonds with surfaces despite challenging conditions. Unlike standard glues requiring dry surfaces and stillness, oyster adhesive thrives in wet, dynamic environments through molecular interactions that resist both erosion and mechanical stress.

Marine biology observation sparked idea that human body’s moist, blood-rich environment mirrors challenges oysters face underwater. Bones exist in fluid-filled spaces where bleeding occurs during surgery and tissues constantly move with breathing, heartbeat, and muscle contractions.

Lin translated natural adhesive principles into medical application by identifying which chemical properties allowed oysters to succeed where synthetic materials failed. Research team reverse-engineered the biological mechanism to create substance that bonds in conditions identical to surgical sites inside living bodies.

Why Traditional Fracture Surgery Takes So Long

Metal plate insertion demands large incisions exposing entire fracture zones to surgeon access. Hours pass as doctors position fragments, drill holes for screws, and attach hardware that will hold everything together during months-long healing process.

Surgeons struggle aligning small bone fragments precisely because pieces slip, rotate, or disappear into surrounding tissue during manipulation. Conventional tools designed for larger bones prove useless when dealing with shattered areas containing dozens of tiny fragments.

Professor Pan Xunwu explained the problem: “Conventional fracture treatment requires fixing bones with metal, making it difficult to precisely align small bone fragments and time-consuming. In the process, bone fragments were often lost, reducing bone mass and ultimately negatively impacting patients’ quality of life.”

Bone mass lost during reconstruction procedures never returns, leaving patients with weaker skeletal structures than before injury. Extended surgery time increases infection risks, anesthesia exposure, and complications from tissue trauma caused by extensive surgical access requirements.

Second surgery needed year later adds expense, recovery time, and additional risks when doctors remove plates and screws after healing completes. Hardware removal requires another operation with its own infection dangers, scarring, and weeks of restricted activity.

Medical Adhesive Works Where Others Fail

Bone-02 bonds successfully in blood-rich surgical environments where other adhesives wash away or fail to set properly. Blood flow that interferes with conventional medical glues presents no obstacle to adhesive designed specifically for wet conditions.

Chemical interaction occurs between glue molecules and bone mineral surface regardless of fluid presence surrounding application site. Molecular bonds form as adhesive contacts bone, creating connections that strengthen rapidly even while blood circulates through area.

Lin Xianfeng described performance capabilities: “The adhesive can achieve precise fixation within two to three minutes, even in a blood-rich environment.”

Setting time measured in minutes rather than hours allows surgeons to complete procedures quickly and verify successful bonding before closing incisions. Immediate hardening means fragments stay positioned correctly throughout entire healing process without shifting or separating.

Strength Tests Reveal Impressive Performance

Maximum bonding force exceeds 400 pounds (181 kilograms) when researchers tested adhesive failure points under controlled laboratory conditions. Engineers applied increasing loads until bonds broke, documenting force required to separate glued bone surfaces.

Shear strength reaches 0.5 megapascals, indicating resistance to sliding forces that try pushing bonded surfaces past each other laterally. Bones experience shear stress during normal activities as muscles pull in different directions and body weight shifts during movement.

Compressive strength hits 10 megapascals, proving ability to withstand crushing forces that press directly on bonded areas. Weight-bearing bones in legs and spine face substantial compression during walking, standing, and lifting activities.

Numbers prove potential to replace metal implants entirely for many fracture types. Mechanical testing confirmed that adhesive bonds match or exceed strength requirements for holding bones together during healing under realistic physical stress conditions.

Over 150 Patients Already Treated Successfully

Multi-center randomized controlled clinical trials enrolled patients across multiple hospital systems to test effectiveness under varied conditions. Different surgeons, equipment, and patient populations provided rigorous evaluation of whether results could be replicated beyond single research center.

Excellent safety profiles emerged from trials with minimal adverse reactions or complications. Patients tolerated injections well without allergic responses, tissue rejection, or inflammatory problems that often plague foreign materials introduced into bodies.

Three-month follow-ups showed complete healing without complications across patient population. X-rays confirmed solid bone union at fracture sites with no gaps, misalignments, or healing delays compared to traditional metal fixation methods.

Real patients recovering faster than traditional methods reported less pain, quicker return to normal activities, and satisfaction with cosmetic outcomes from smaller surgical scars.

Wrist Fracture Healed Through Tiny Incision

Patient with comminuted wrist fracture received treatment via 3 centimeter opening barely larger than standard injection site. Shattered bone fragments scattered across wrist joint area posed challenge that would normally require extensive surgical access.

Surgeon injected Bone-02 directly into fracture zone where adhesive flowed around fragments, coating surfaces and bonding pieces together. Entire procedure from incision to closure completed in three minutes flat including time for injection and verification of proper fragment positioning.

Full wrist function restored after healing period ended, allowing patient to resume normal hand use without restrictions. Range of motion, grip strength, and pain levels all returned to pre-injury baseline without complications or long-term limitations.

Traditional approach would require large incision exposing entire wrist joint, metal plate placement with multiple screws, and removal surgery scheduled for year later. Extended recovery time, prominent scarring, and hardware complications would accompany conventional treatment approach.

Biodegradable Material Disappears as Bone Heals

Body absorbs adhesive over approximately six months through natural metabolic processes that break down biocompatible materials. Immune system recognizes components as non-threatening and gradually clears them through normal waste removal pathways.

No foreign objects remain permanently embedded in skeletal system after healing completes. Patients avoid carrying metal hardware for life or undergoing removal procedures to extract plates and screws once bones mend.

Natural healing proceeds without interference from permanent implants that can cause long-term problems. Metal fatigue, corrosion, allergic reactions, and interference with medical imaging all vanish as concerns when no lasting foreign materials exist inside body.

Elimination of second surgery for hardware removal saves thousands of dollars per patient while avoiding risks associated with additional anesthesia exposure and surgical site infections.

Small Bone Fragments Finally Get Proper Treatment

Conventional tools cannot fix tiny shattered pieces smaller than screw heads or too fragile for drilling. Surgeons often abandon attempts to secure smallest fragments, accepting their loss as inevitable part of fracture treatment.

Bone-02 reaches and bonds fragments too small for mechanical fixation through injectable delivery that flows into spaces inaccessible to surgical instruments. Adhesive coats all surfaces within fracture zone regardless of fragment size or location.

Lin Xianpeng noted broad applications: “This material is suitable for treating fractures of all sizes and body parts, particularly small bone fragments difficult to fix with conventional tools.”

Precision alignment previously impossible becomes achievable when adhesive holds everything exactly where surgeon positions it during injection. No slippage occurs during healing as fragments remain locked in correct orientation from moment adhesive sets.

What Happens Next for Bone-02 Technology

Clinical trials continuing to expand patient populations and fracture types evaluated. Researchers test effectiveness for complex breaks in different bones across diverse patient demographics including children, elderly, and those with underlying health conditions.

Regulatory approval processes in multiple countries will determine timeline for widespread availability outside China. Each nation’s medical device authorization requirements must be satisfied through additional testing and documentation before Bone-02 reaches international markets.

Potential applications beyond fracture repair being explored include dental implant stabilization, spinal fusion enhancement, and joint reconstruction procedures. Any situation requiring bone-to-bone bonding could benefit from adhesive technology proven effective for fractures.

Timeline for widespread availability remains uncertain as regulatory reviews, manufacturing scale-up, and surgeon training programs take years to complete. Even promising technologies face lengthy approval processes ensuring safety and effectiveness before entering routine medical practice worldwide.

Loading...