Researchers Found a Method to Turn Metals Transparent, Opening Doors for Stronger Electronic Device Screens and Tech

Something impossible just became possible in a laboratory halfway around the world. Scientists accomplished what sounds like magic – making solid metal disappear before your eyes while keeping all its strength. No complicated machinery. No massive industrial equipment. Just a tiny droplet smaller than a pinhead and some basic electrical current.

What happened in those few minutes could change every device you own and dramatically reduce the environmental cost of making them. Your smartphone, your laptop screen, your car windows, even your home’s energy efficiency – all could transform because of this breakthrough that uses 99% fewer chemicals than current methods.

But here’s what makes this discovery truly remarkable: it puts the power to demand cleaner technology directly in your hands as a consumer. Every purchase decision you make can now drive demand for manufacturing processes that protect our planet rather than poison it.

A Single Droplet Changes Everything We Know About Metal

Aluminum surrounds us everywhere – from the can holding your morning coffee to the circuits powering your devices. Yet until now, making this common metal transparent required drowning entire sheets in vats of harsh chemicals or expensive vacuum chambers that consume enormous amounts of energy.

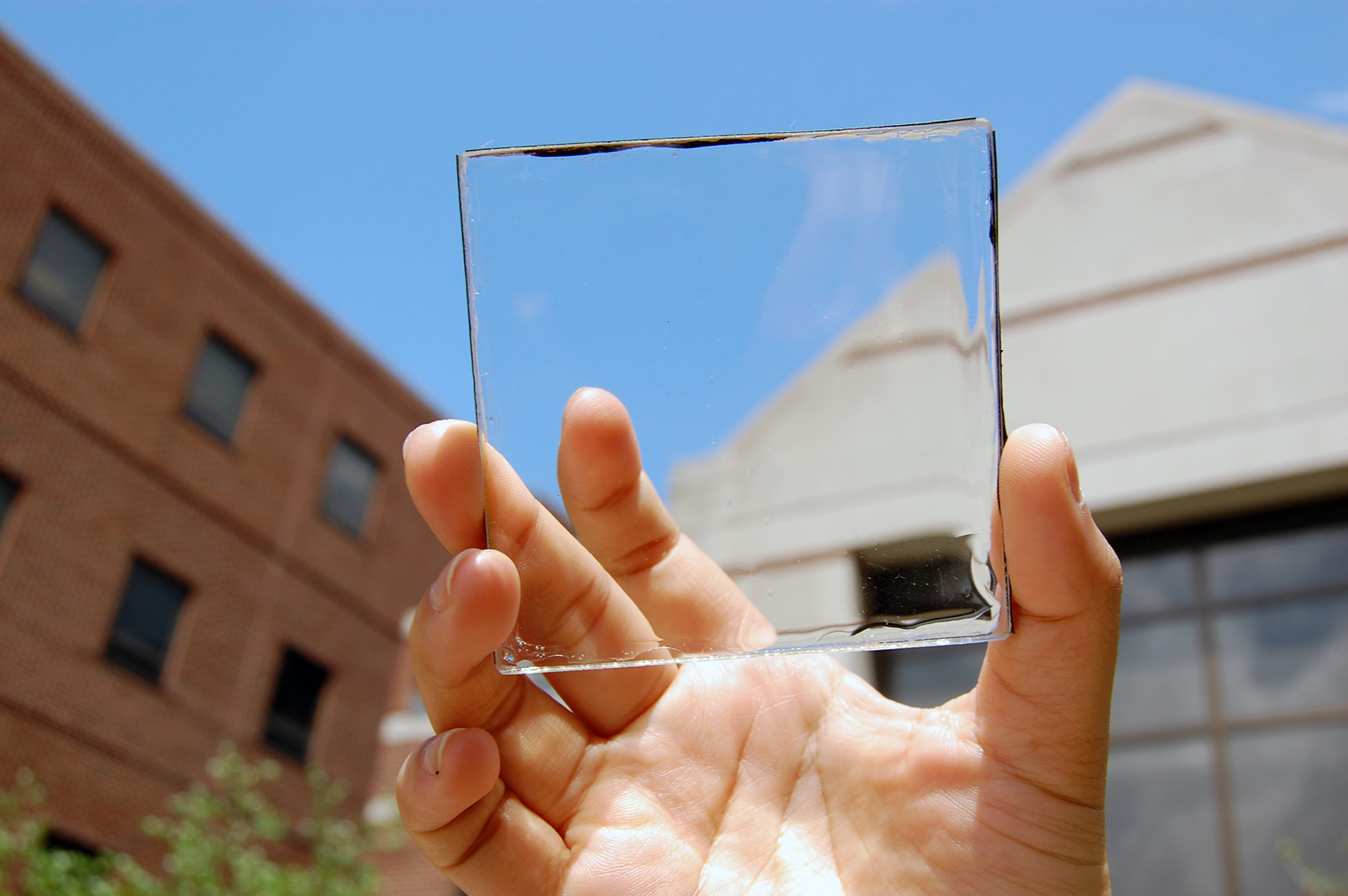

Under a microscope, researchers watched something fascinating unfold. Rather than changing all at once, the aluminum began transforming at the edges of the acid droplet first. Transparency crept inward like fog clearing from a window, creating a perfect circular spot that let light pass through while maintaining the metal’s strength.

Scientists found they could control everything by adjusting just two simple factors: voltage and time. Too much electricity spread the droplet too wide, creating larger but lower-quality transparent areas. Too little power required excessive patience. But at exactly 2 volts for 10 minutes, they achieved the perfect balance – high-quality transparent spots that outperformed traditional methods.

Your Phone Screen Could Soon Be Stronger Than Ever

Picture dropping your phone and watching it bounce harmlessly off concrete. Imagine laptop screens that never scratch, no matter how carelessly you toss them in your bag. Transparent aluminum oxide makes this possible by combining glass-like clarity with metal’s durability.

Tests showed the material allows over 70% of visible light to pass through – nearly as clear as glass itself. But it offers an additional benefit that could slash your energy bills: while letting through light you can see, it blocks invisible near-infrared radiation that carries heat.

Applications extend far beyond phone screens. Solar panels could become more efficient with transparent aluminum coatings that protect sensitive components while allowing maximum light penetration. Camera sensors could resist scratching while maintaining optical clarity. Car windows might regulate interior temperature naturally, reducing air conditioning demands.

Energy-efficient buildings could incorporate transparent aluminum windows that illuminate rooms while preventing heat buildup. For homeowners, this could mean dramatically lower cooling costs during summer months – putting money back in your pocket while reducing your carbon footprint.

From Chemical Waste Mountains to Single Droplets

Manufacturing transparent materials traditionally requires environmental devastation. Conventional methods immerse entire aluminum sheets in massive acid baths, generating tons of chemical waste that must be treated, stored, or disposed of safely. Vacuum-based techniques consume enormous amounts of electricity while requiring expensive specialized equipment.

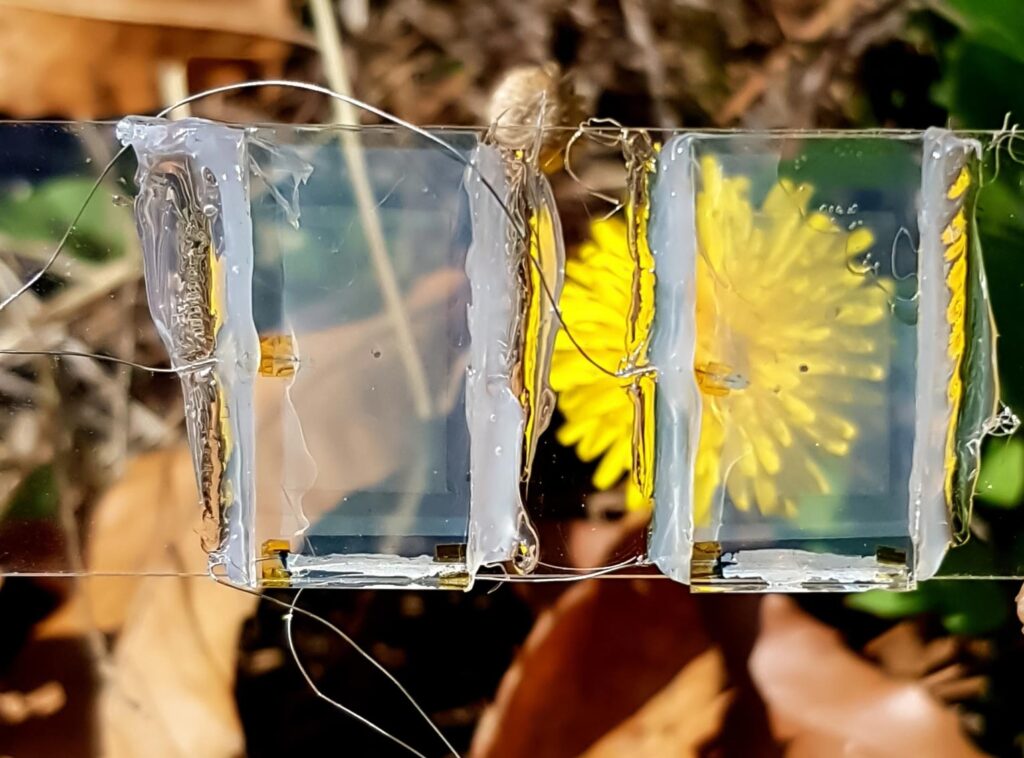

Droplet-scale anodization flips this wasteful process completely. Instead of gallons of chemicals, it uses a single microdroplet containing less acid than exists in one drop of lemon juice. Instead of industrial power consumption, it operates on just 2 volts – less electricity than two AA batteries provide.

Even more impressively, the technique creates better results than traditional methods. Limited acid quantities create more controlled environments for transformation, preventing irregularities that occur when excessive chemicals move around unpredictably. Scientists discovered their droplet method produced smoother, more uniform transparent areas than conventional approaches.

Green Revolution Hidden in Your Pocket

Every device you buy represents a choice about what kind of future you want to support. Traditional electronics manufacturing consumes vast quantities of water, energy, and chemicals while generating toxic waste that contaminates soil and groundwater for generations.

Your purchasing decisions create market demand that drives innovation toward cleaner production methods. When consumers choose products made using sustainable techniques, manufacturers respond by investing in greener technologies. When we prioritize environmental responsibility alongside performance and price, we accelerate the development of planet-friendly alternatives.

“This droplet-scale anodization technique can be extended to other transparent metal oxides, providing an environmentally friendly and cost-effective fabrication route toward sustainable electronics and other related applications.” Each time you research a company’s environmental practices before buying, you exercise power that shapes how products get made.

Consider the ripple effects of your choices. Demand for sustainably-produced electronics encourages development of cleaner manufacturing processes. Companies compete to offer greener alternatives when consumers make environmental impact a priority. Your individual accountability multiplies through market forces to create systemic change.

Energy-Efficient Windows That Actually Make Sense

Home energy consumption represents one of the largest sources of individual carbon emissions. Heating and cooling account for nearly half of typical household energy use, much of which results from inefficient windows that let heat escape in winter and enter during summer.

Transparent aluminum’s dual nature – allowing visible light while blocking heat-carrying infrared – could revolutionize residential energy efficiency. Windows incorporating this material would illuminate homes naturally while preventing unwanted temperature changes. Air conditioning systems would run less frequently during hot weather. Heating costs could drop during cold seasons.

For environmentally conscious homeowners, transparent aluminum windows represent an opportunity to dramatically reduce energy consumption without sacrificing comfort or natural lighting. Lower utility bills provide financial incentives while reduced energy demand decreases fossil fuel consumption and carbon emissions.

Building contractors and architects could offer clients genuinely sustainable options that improve both environmental performance and long-term operating costs. Smart consumers will seek out these innovations, driving market adoption and making greener building materials mainstream.

Small Lab, Big Impact: Democratizing Green Technology

Breakthrough’s simplicity makes it accessible worldwide, not just in wealthy countries with advanced industrial infrastructure. Basic laboratory equipment – a power supply, platinum wire, and dilute acid – provides everything needed to create transparent aluminum oxide.

Accessibility matters enormously for global environmental progress. When clean technologies require massive capital investments or specialized facilities, only large corporations in developed nations can implement them. But when innovations work with modest equipment, smaller companies worldwide can participate in sustainable manufacturing.

Researchers suggest the same approach could work with other metals, creating various transparent metal oxides with different properties. Some might offer superior electrical conductivity for advanced electronics. Others could provide enhanced durability for aerospace applications. Each metal oxide expands the toolkit available for sustainable innovation.

Educational institutions and small companies can experiment with transparent metal production without massive infrastructure investments. Entrepreneurs in developing countries could establish manufacturing operations that compete globally while maintaining environmental responsibility.

One Innovation Transforms Multiple Industries

Transparent aluminum applications extend far beyond consumer electronics into industries that shape modern life. Aerospace companies could develop stronger, lighter aircraft windows that improve fuel efficiency. Automotive manufacturers might create more aerodynamic vehicles with transparent aluminum components that reduce wind resistance.

Self-driving cars depend on optical sensors that must remain clear and functional in harsh conditions. Transparent aluminum coatings could protect these components from scratching while maintaining the sensitivity required for safe autonomous navigation. As transportation becomes increasingly automated, such durability improvements become essential for public safety.

Solar energy installations could benefit from transparent aluminum protective coatings that extend panel lifespans while maintaining maximum efficiency. Wind turbines might incorporate transparent aluminum components that resist environmental damage while reducing maintenance requirements.

“As consumers and regulators increasingly push for greener manufacturing processes, techniques that minimize chemical usage and waste are becoming more valuable to industry.” Market pressure from environmentally conscious consumers drives companies to adopt cleaner production methods across multiple sectors simultaneously.

Your Consumer Choices Drive Demand for Cleaner Tech

Individual purchasing decisions aggregate into market signals that guide corporate investment priorities. When consumers consistently choose products made using sustainable methods, companies redirect research and development toward greener technologies. When environmental considerations influence buying decisions, manufacturers compete to offer cleaner alternatives.

Research your electronics purchases before buying. Ask companies about their manufacturing processes. Support businesses that prioritize environmental responsibility in production methods. Choose products designed for longevity rather than planned obsolescence.

Consider the total lifecycle impact of devices you purchase. Products built to last longer reduce overall resource consumption and waste generation. Items manufactured using clean processes prevent environmental contamination during production. Devices designed for repairability extend useful life while reducing electronic waste.

Share information about sustainable manufacturing with friends and family. Environmental progress accelerates when more people make informed decisions based on production methods rather than just price and features. Your advocacy multiplies your individual impact by influencing others’ choices.

What This Means for Conscious Living

Transparent aluminum won’t appear in consumer products immediately, but current research demonstrates how individual choices and environmental responsibility intersect with scientific innovation. Supporting companies that invest in sustainable manufacturing encourages continued development of planet-friendly technologies.

Stay informed about emerging green technologies in electronics and other industries. When transparent aluminum products become available, choose manufacturers that embrace environmentally responsible production methods. Advocate for government policies that incentivize clean manufacturing while penalizing wasteful practices.

Make conscious decisions about device replacement cycles. Resist marketing pressure to upgrade frequently when current devices function adequately. Proper care and maintenance extend product lifespans while reducing demand for new manufacturing. Recycling electronic waste through certified programs recovers valuable materials while preventing environmental contamination.

Your daily choices create the future we all share. Every sustainable purchase, every company you research, every conversation about environmental responsibility contributes to systemic change. Transparent aluminum represents just one example of how scientific innovation and consumer accountability can work together to protect our planet while improving our lives.

Science provides the tools. Individual responsibility provides the market demand. Together, they create possibilities for a more sustainable future where technology serves both human needs and environmental protection.

Loading...